Stahl Specialty Company - An Overview

Table of ContentsStahl Specialty Company Fundamentals ExplainedSome Ideas on Stahl Specialty Company You Need To KnowStahl Specialty Company Can Be Fun For AnyoneWhat Does Stahl Specialty Company Do?The Definitive Guide to Stahl Specialty Company

There are several small distinctions in between wrought and cast aluminum alloys, such as that actors alloys can consist of more considerable quantities of other steels than wrought alloys. Yet the most significant distinction between these alloys is the construction procedure with which they will certainly most likely to provide the end product. Apart from some surface treatments, cast alloys will certainly leave their mold and mildew in virtually the specific strong type preferred, whereas wrought alloys will undergo several adjustments while in their solid state.If you think that a functioned alloy may be the most effective for your task, take an appearance at some of our articles that clarify more about certain wrought alloys, such as Alloy 6061 and Alloy 6063. On the various other hand, if you believe an actors alloy would certainly be better for you, you can discover more concerning some actors alloys in our Alloy 380 and Alloy 383 articles (coming quickly).

Having the experience and industry knowledge to craft your castings for optimal production and top quality end results will simplify the job. Making light weight aluminum castings requires a facility collection of processes to accomplish the ideal outcomes. When choosing a brand-new aluminum shop to companion with, guarantee they have considerable sector experience and are knowledgeable about all aspects of the aluminum spreading procedure: layout, manufacturing, product analysis, and product testing.

The Greatest Guide To Stahl Specialty Company

The factory ought to also have a tried and tested track document of supplying exceptional items that satisfy or exceed consumer expectations. Quality control needs to likewise go to the top of your listing when choosing a light weight aluminum factory. By working with a certified foundry that complies with the criteria for top quality control, you can safeguard the honesty of your product and guarantee it satisfies your specifications.

By picking a business that offers services that fulfill or exceed your product requirements, you can be certain that your project will be finished with the utmost precision and performance. Different parts call for different manufacturing techniques to cast light weight aluminum, such as sand casting or die spreading.

Die casting is the name provided to the procedure of creating intricate steel elements via usage of molds of the element, additionally understood as dies. It produces even more elements than any type of other procedure, with a high level of accuracy and repeatability. additional hints There are 3 sub-processes that fall under the category of die casting: gravity pass away casting (or permanent mold and mildew casting), low-pressure die casting and high-pressure die casting.

After the purity of the alloy is tested, passes away are developed. To prepare the passes away for casting, it is essential that the dies are tidy, so that no deposit from previous productions remain.

The pure steel, additionally called ingot, is included in the heater and maintained at the molten temperature level of the steel, which is then transferred to the injection chamber and injected into the die. The stress is after that preserved as the metal strengthens - Casting Foundry. When the metal solidifies, the cooling procedure starts

The thicker the wall of the component, the longer the cooling time due to the quantity of indoor steel that additionally requires to cool. After the element is completely cooled, the die halves open and an ejection mechanism pushes the element out. Adhering to the ejection, the die is closed for the following injection cycle.

Stahl Specialty Company for Dummies

Today, leading makers utilize x-ray screening to see the entire inside of elements without cutting right into them. To obtain to the finished item, there are three main alloys used as die casting material to pick from: zinc, aluminum and magnesium.

Zinc is one of the most previously owned alloys for die casting due to its reduced cost of raw materials. Its deterioration resistance also enables the parts to be long enduring, and it is one of the more castable alloys due to its lower melting factor - Aluminum Casting.

8 Simple Techniques For Stahl Specialty Company

As discussed, this alloy is among one of the most generally used, yet manufactures will, at times, choose aluminum over zinc due to aluminum's manufacturing advantages. Aluminum is highly economical and one of the more versatile alloys. Aluminum is made use of for a variety of various items and markets anything from home window frameworks to aerospace materials.

Molly Ringwald Then & Now!

Molly Ringwald Then & Now! Tahj Mowry Then & Now!

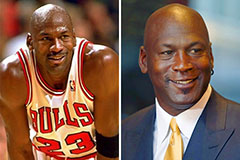

Tahj Mowry Then & Now! Michael Jordan Then & Now!

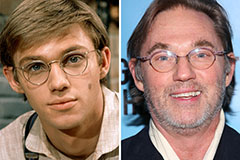

Michael Jordan Then & Now! Richard Thomas Then & Now!

Richard Thomas Then & Now! Tina Louise Then & Now!

Tina Louise Then & Now!